Smart3DCad

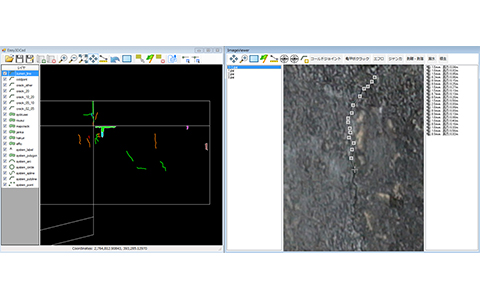

With ”Smart3DCad”, anyone can draw easily using 3D data.

By using 3D model created from UAV photographed images or 3D laser point clouds, anyone can easily draw. Simplified drawing by field operators is possible in emergencies, such as disasters. Even a person who is unfamiliar with CAD can make drawings in less than an hour of training. It is also possible to make drawings while checking the overhead view. Drawing data is acquired in 3D coordinates. Since it is a low-cost product, many people can use it. After saving to DXF/SXF data, the client can edit with CAD he/she usually uses.

Features

As new functions, we have “point cloud noise filtering function”, “TIN generating function”, “shadow display function”, “contour line output function”, and “3D distance/area measuring function”. It is possible to make a drawing with point cloud data (LAS) obtained with a handy laser, UAV, MMS, and fixed laser as a background. TIN is generated from point clouds and shadow display is possible. Contour lines can be generated and output automatically. It can output 2D shapes on specified section line.

PhotoCrack

With ”PhotoCrack”, drawing can be realized while checking crack width using photographs.

It is a CAD that loads images taken by a UAV or a fixed camera to CAD with our original crack-scale and makes drawings while checking the width of cracks. It can apply to dams, bridges and buildings. With this, it can create an expanded drawing of deformation. “Crack”, “cold joint”, “efflorescence”, “alligator crack”, “rock pocket”, “exfoliation/falling”, “water leak” and “vegetation” can be indicated by pressing the button for the specific damage type.

Features

PhotoCrack imports existing CAD data such as dams and bridges. If there is no CAD data, it can trace a completion drawing (paper-based) and convert it to CAD. By loading high quality digital photo images and setting it, it is possible to draw while displaying the crack scale on the images and checking the width of the cracks. Just by tracing the cracks on the image, it can represent shapes of cracks and exfoliations on the CAD. The crack data can be used as an expansion representation of deformation.